According to the storage medium, energy storage technology is mainly divided into mechanical energy storage, electrical energy storage, chemical energy storage, etc., various energy storage methods have their own advantages and disadvantages, adapted to different application scenarios, in which lithium-ion battery is expected to become the mainstream technology for development due to its high energy density, high charging and discharging efficiency, fast response speed, industry chain equipped with a perfect, not subject to geographical constraints and other advantages. The lithium-ion energy storage module PACK technology is the most important technical means of lithium-ion battery.

What is an energy storage battery PACK?

Lithium-ion battery PACK, also known as battery module, is a lithium-ion battery production process, which refers to connecting multiple lithium-ion monomer cell sets through parallel-series connection to form a particular shape according to the customer’s requirements, and its main principle is to integrate the battery chip, battery management system, battery management chip and other components together to form a complete battery pack to achieve energy storage and output. The most important technologies of energy storage battery PACK are reflected in the overall structural design, welding and processing process control, protection level, active thermal management system, etc. It is widely used in the fields of grid peaking, electric transportation and distributed energy.

Composition of Lithium Battery PACK

- Battery Module

If we compare a PACK to a human body, then the module is the “heart”, responsible for storing and releasing electrical energy. - Electrical System

Mainly consists of connecting copper liner, high-voltage wiring harness, low-voltage wiring harness, and electrical guarantee devices. The high-voltage harness can be regarded as the “arteries and blood vessels” of the battery PACK, which continuously delivers battery power to the end loads, while the low-voltage harness can be regarded as the “neural network” of the battery PACK, which transmits real-time detection signals and control signals. - Thermal management system

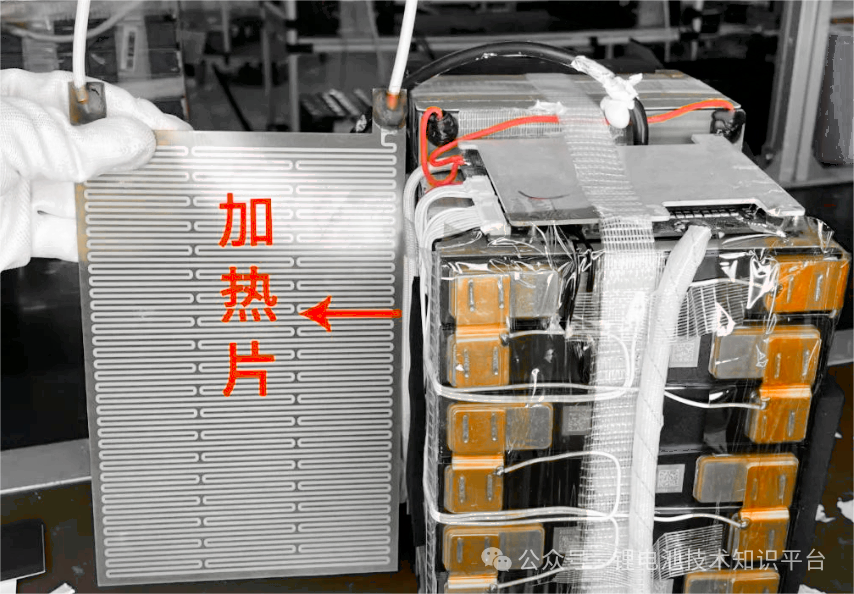

Thermal management system mainly has two ways of air-cooling and liquid cooling, while liquid cooling can be divided into cold plate liquid cooling and immersion liquid cooling. The thermal management system is equivalent to installing an air conditioner to the battery PACK. The battery will generate heat in the discharge mode, and to ensure that the battery works in a reasonable ambient temperature and enhance the battery cycle life, the system temperature difference is generally required to be ≤5℃. - Case

Mainly consists of case, case cover, metal bracket, panel and fixing screws, can be regarded as the “skeleton” of the battery PACK, play a role in supporting, resisting mechanical shock, mechanical vibration and environmental protection. It can be regarded as the “skeleton” of the battery PACK, which plays the roles of support, resistance to mechanical impact, mechanical vibration and environmental protection. - BMS

Battery management system” is the abbreviation of “battery management system”, i.e. battery management system, which can be compared to the battery’s The battery management system can be compared to the battery’s “brain”. It is mainly responsible for measuring the battery’s parameters such as voltage, current and temperature, as well as equalization and other functions. The data can be transmitted to MES.

Characteristics of lithium battery PACK

- High Energy Density: Li-ion batteries have high energy density and can store a large amount of energy in a relatively small volume and weight, which is suitable for energy storage.

- High Safety: Li-ion battery storage module PACK adopts advanced BMS system and safety measures, which can realize the monitoring, protection and fault detection of battery monomer, and can effectively reduce the safety risk.

- High-efficiency performance: Li-ion battery energy storage module PACK has high charging and discharging efficiency and strong fast response capability, which can realize fast charging and high efficiency energy release, and meet the demand of energy storage system for energy output.

- Scalability: The design of Li-ion battery storage module PACK has good scalability, and the modules can be connected in parallel or in series as needed to meet the needs of different sizes and powers.

- Environmental protection and energy saving: Li-ion battery storage module PACK is a clean energy solution that is environmentally friendly and can reduce dependence on traditional energy resources.

Four Types of Protection for Batteries from PACK Battery Packs

- Overcharge Protection

When the external charger, through the Li-ion battery PACK pack PACK+ and PACK- to charge it, after a period of time, the voltage of the Li-ion battery will gradually rise, until it rises to the Li-ion battery charging cut-off voltage, the The charger will stop charging. However, in abnormal circumstances, the charger has been still charging, the lithium battery voltage may continue to rise, if it rises to the chip’s protection voltage, it will trigger the chip’s internal comparator, making the chip shut down the pipeline, the circuit can not continue to charge, so as to protect the function of charging. - Over-discharge protection

When the lithium battery PACK pack is powered to the load, after a period of time, the voltage of the lithium battery will slowly drop to a specific voltage, the chip will be triggered to start the chip’s internal comparator, closing the internal specific pipeline, thus preventing the over-discharge of the lithium battery. The circuit is disconnected, thus preventing the over-discharge of the lithium battery. - Charge Overcurrent Protection

The chip detects the voltage at the VDD pin to determine whether the voltage of the lithium battery is overcharged or overdischarged, and similarly, by detecting the voltage at the V- pin, the chip determines whether the lithium battery is charging or discharging current. The same way by detecting the voltage of V-pin, we can judge whether the current of Li-ion battery is charging or discharging overcurrent. During charging, if the charging current makes the resistor voltage exceed the chip’s threshold, the chip will close the channel and force the charging function to shut down, so as to protect the battery from overcurrent charging. - Discharge Overcurrent Protection

When the Li-ion PACK pack is supplying power to the load, if the load consumes too much current, causing the voltage at the V-pin to exceed the discharge overcurrent protection threshold voltage, the chip’s protection mechanism will be triggered to shut down the corresponding channel and the circuit will be disconnected.