Accurate cell sorting is crucial for ensuring the stability and safety of lithium batteries. Before performing cell sorting, it is important to fully understand the relevant parameters of the cells and select the appropriate matching based on the requirements of electronic devices. Factors such as internal resistance and internal voltage drop should be considered for precise matching, ensuring the stability and safety of the battery pack while achieving optimal performance and longevity.

Concept of Cell Sorting

Cell sorting involves classifying and assembling cells based on similar voltage, internal resistance, capacity, and internal voltage drop. The performance of the battery pack, including its stability, safety, and capacity, is directly influenced by the cell sorting scheme and matching selection.

Cell Parameters

Before cell sorting, it is necessary to understand the relevant parameters of the cells. There are three fundamental parameters for cells: capacity, internal resistance, and internal voltage drop. Capacity refers to the amount of charge stored in the cell, usually measured in milliampere-hours (mAh). Internal resistance represents the voltage drop experienced when current passes through the cell and reflects the cell’s electrical performance. Internal voltage drop indicates the extent to which the cell’s voltage decreases with the load, representing the complexity of the cell’s electrochemical reaction.

Battery Pack Capacity

Determining the capacity of the battery pack is the first step, based on the specifications of the electronic device. Then, other parameters of the cells can be considered for matching. For example, for a smartphone with a typical battery capacity between 2000mAh and 5000mAh, we can choose two different capacity cells for matching, such as a 2000mAh cell and a 3000mAh cell. This not only meets the capacity requirements of the smartphone but also ensures a long lifespan and stability of the battery pack.

Internal Resistance and Internal Voltage

During cell sorting, it is advisable to match cells with similar internal resistance and internal voltage, minimizing the voltage differences between cells and enhancing the stability and safety of the battery pack.

Considerations

Different brands, models, and specifications of lithium batteries have distinctive performance characteristics. Therefore, it is essential to pay attention to differences and compatibility among various lithium batteries when performing cell sorting, ensuring safety and stability.

Steps

Selection of Cell Specifications: Before cell sorting, thoroughly understand the specifications of the cells. Common cell specifications include capacity, voltage, internal resistance, and discharge rate. Different applications require different cell specifications to meet specific demands. Therefore, understand the operating environment and performance requirements of the battery and choose appropriate cell specifications.

Cell Matching

Match cells with similar performance parameters during battery assembly, avoiding performance imbalance caused by large differences between cells. Generally, the capacity, internal resistance, voltage, and other parameters of the cells should be similar to ensure optimal performance and lifespan of the battery pack.

Cell Sorting Methods

Cell sorting can be accomplished through serial or parallel connections. Serial connection increases the voltage by connecting the positive and negative terminals of multiple cells in sequence, while parallel connection increases the capacity by connecting the positive and negative terminals of multiple cells separately. Choose the appropriate sorting method based on actual requirements and ensure that each cell has similar specifications to maintain the performance and safety of the battery pack.

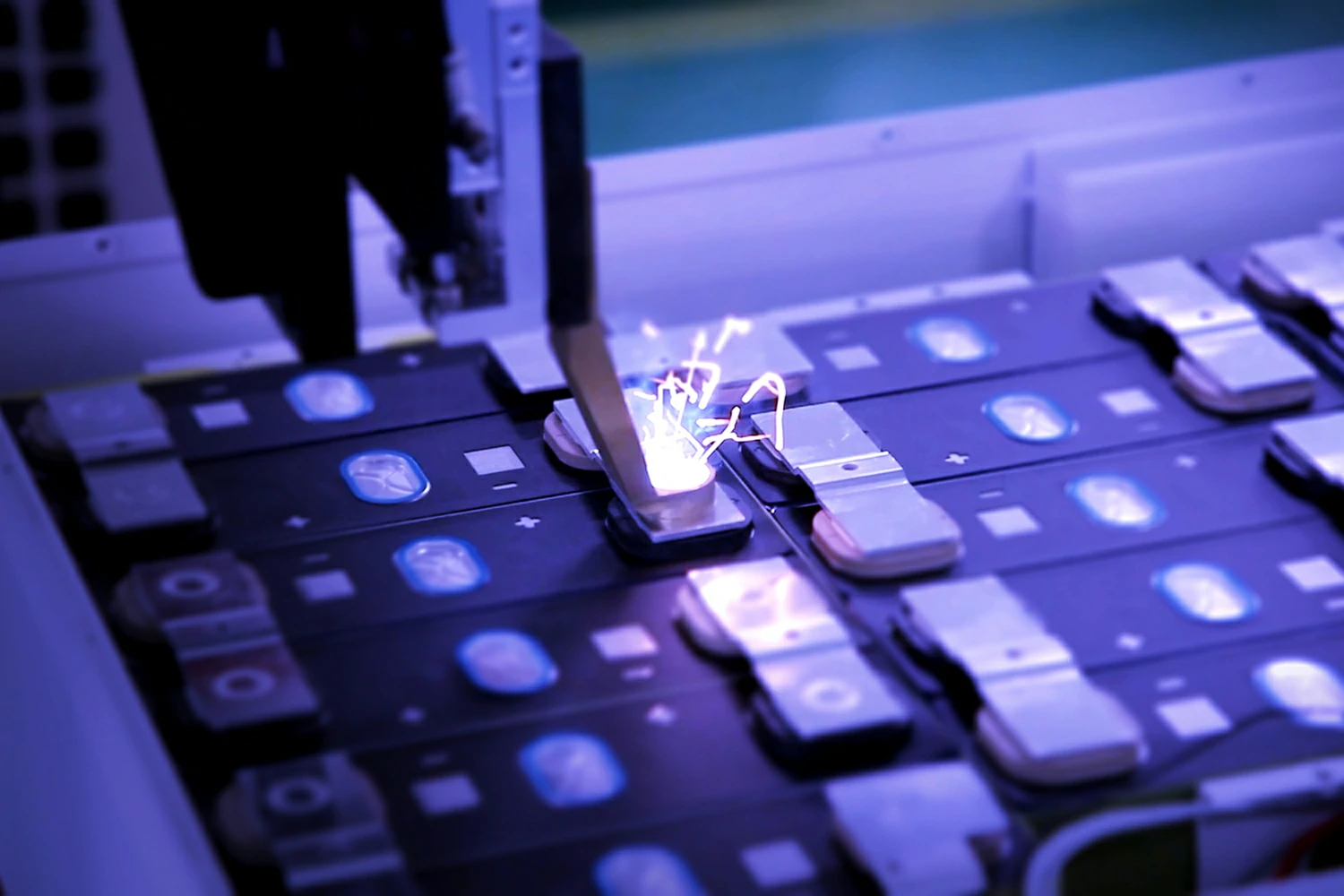

Cell Sorting Testing

After cell sorting, conduct precise testing on the battery pack using sophisticated equipment to evaluate the performance and safety of each cell. Common test items include voltage balance testing, internal resistance testing, and discharge performance testing. Through these tests, potential issues can be identified and promptly addressed.

Conclusion:

Accurate matching and sorting of cell specifications are crucial in lithium battery manufacturing. Proper selection of cell specifications, precise cell matching, selection of suitable sorting methods, and necessary testing ensure the quality and stability of the battery pack. During battery assembly, strictly adhere to the principle of accurate specification matching to ensure the quality and stability of the battery pack.