Lithium-ion battery PACK technology plays an important role in the energy storage industry. It involves connecting multiple lithium-ion individual battery cells in series and parallel to form a battery module, while taking into account the system’s mechanical strength, thermal management, and BMS matching. Its composition mainly includes individual battery modules, electrical systems, thermal management systems, enclosures, and BMS.

1.Define

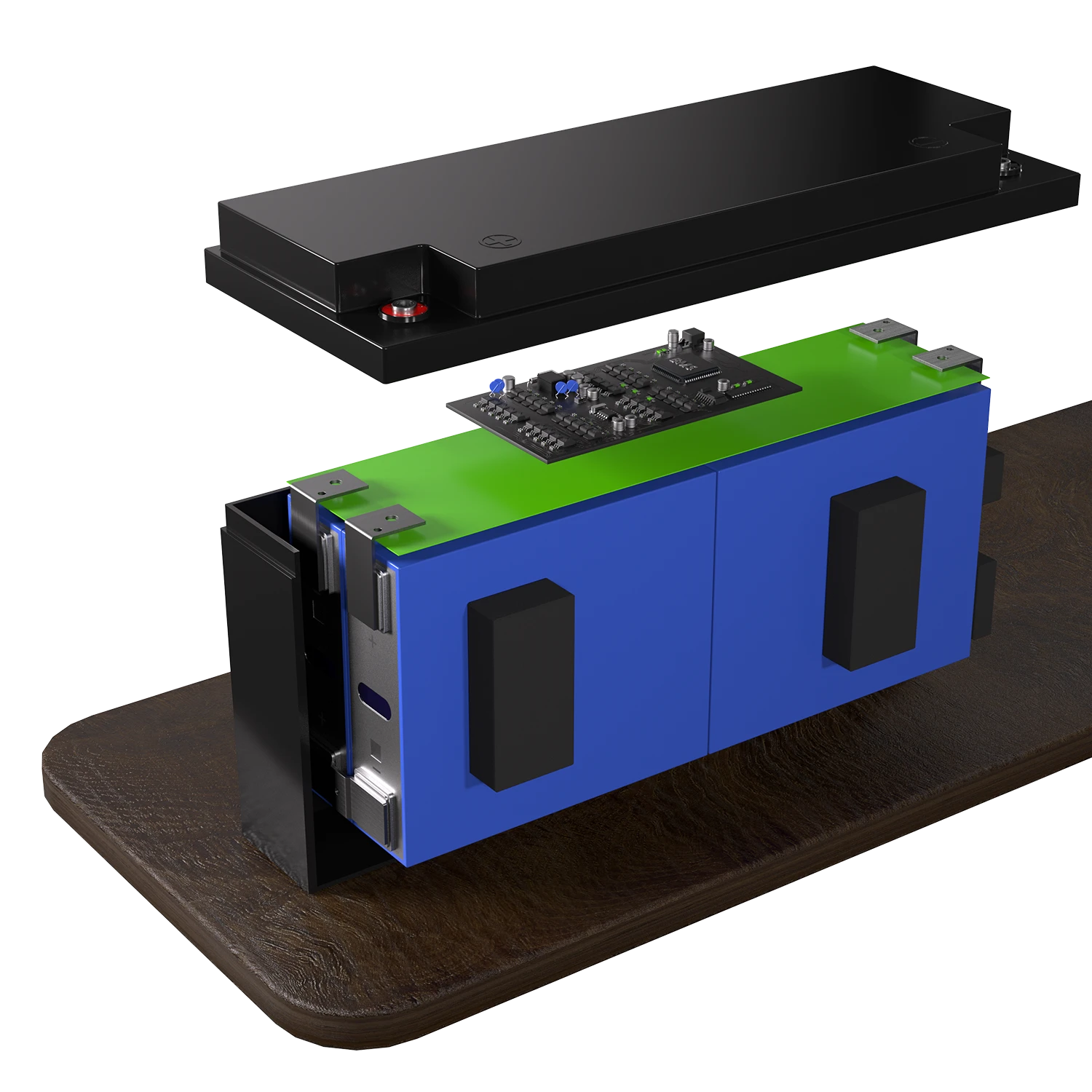

The lithium-ion battery PACK, also known as a battery module, is a manufacturing process for lithium-ion batteries, encompassing packaging, encapsulation, and assembly. It involves connecting multiple individual lithium-ion battery cells in series and parallel, while considering aspects such as system mechanical strength, thermal management, and BMS matching. Its important technical aspects lie in overall structural design, welding and processing control, protection levels, and active thermal management systems. For instance, when two batteries are connected in series or parallel to form a specific shape as per customer requirements, it is referred to as a PACK.

2.Composition of lithium battery pack

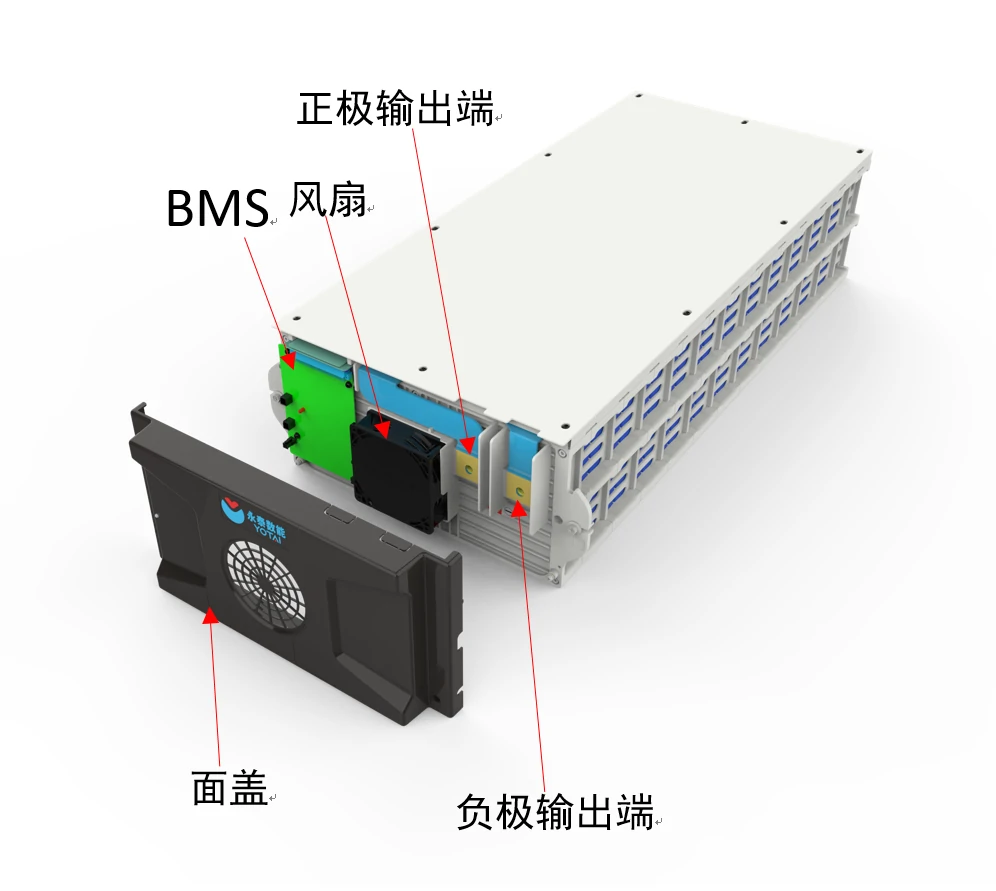

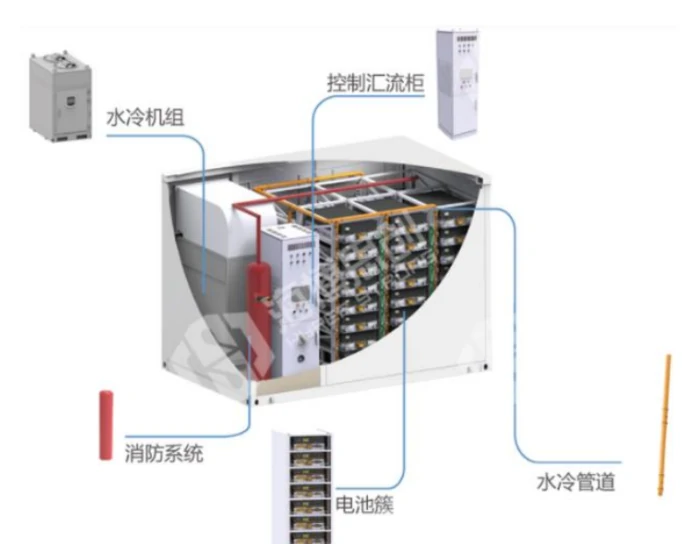

The battery pack consists of several important components, including individual battery modules, electrical systems, thermal management systems, cabinets, and BMS.

Battery Module:

If the battery pack is compared to a human body, then the module is the “heart” responsible for storing and releasing electrical energy.

Electrical system::

It mainly consists of connecting copper strips, high-voltage harnesses, low-voltage harnesses, and electrical assurance devices.

The high-voltage harness can be likened to the “major artery” of the battery PACK, continuously delivering battery power to the end loads. In contrast, the low-voltage harness can be seen as the “neural network” of the battery PACK, transmitting real-time detection signals and control signals.

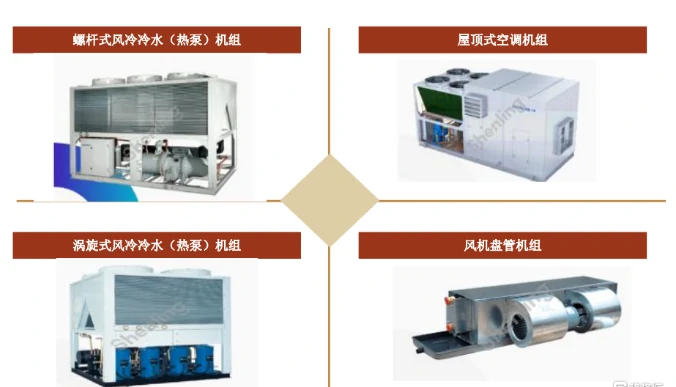

Thermal management system:

The thermal management system mainly includes two methods: air cooling and liquid cooling. Liquid cooling can be further divided into cold plate liquid cooling and immersion liquid cooling. The thermal management system is akin to installing an air conditioning system for the battery PACK.

There are various assembly types of air cooling systems, with the core components mainly being compressors, fans, heat exchangers, etc

The battery generates heat during discharge mode. To ensure that the battery operates at a reasonable ambient temperature and improve its cycling life, the system temperature difference is generally required to be ≤ 5 ℃.

box:

It mainly consists of a box body, a box cover plate, a metal bracket, a panel, and fixing screws, and can be regarded as the “skeleton” of a battery pack, playing a role in supporting, resisting mechanical impact, mechanical vibration, and environmental protection.

BMS:

The Battery Management System can be seen as the ‘brain’ of the battery. Mainly responsible for measuring parameters such as voltage, current, and temperature of the battery, as well as balancing functions. Data can be transmitted to MES.

?3.Characteristics of battery pack

- PACK lithium battery packs require high consistency in battery capacity, internal resistance, voltage, discharge curve, and lifespan.

- The cycle life of the battery pack PACK is lower than that of a single battery.

- Used under limited conditions (including charging, discharging current, charging method, temperature, etc.)

- After the lithium battery pack is formed, the battery voltage and capacity have greatly increased, and it must be protected by charging balance, temperature, voltage, and overcurrent monitoring.

- The battery pack must meet the voltage and capacity requirements required by the design.

PACK method

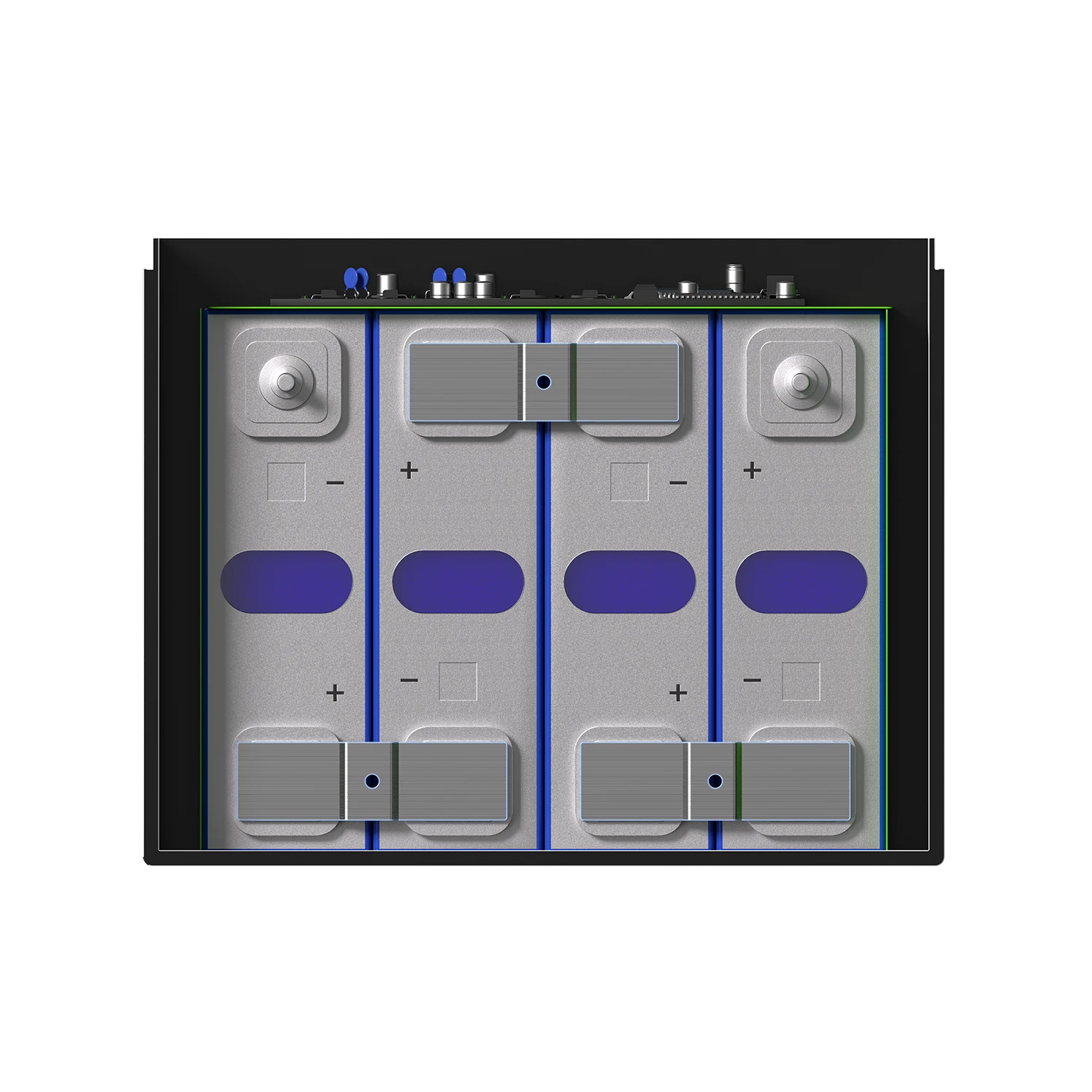

- Series parallel composition: The battery module is composed of individual cells connected in series. Parallel connection increases capacity, voltage remains unchanged, and after series connection, voltage doubles, capacity remains unchanged. For example, if 15 cells with a voltage of 3.2V are connected in series, it is 48V, which is called series boosting. For example, if two cells with a capacity of 50Ah are connected in parallel, there will be 100Ah, which is called parallel expansion.

- Battery requirements: Select the corresponding battery cells according to your own design requirements. The types and models of batteries in parallel and series should be consistent, and the differences in capacity, internal resistance, and voltage values should not exceed 2%. Both flexible packaging batteries and cylindrical batteries require multiple string combinations.

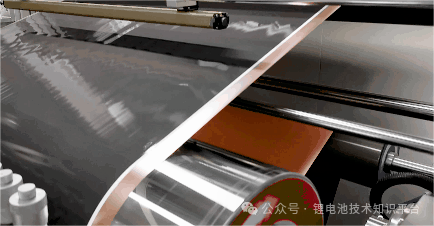

PACK process: There are two ways to achieve battery PACK, one is through laser welding, ultrasonic welding, or pulse welding. This is a commonly used welding method, with the advantage of good reliability but not easy replacement.

The second pulse laser is contacted through elastic metal plates, which has the advantages of no welding and easy battery replacement. The disadvantage is that it may cause poor contact. Considering the production yield, efficiency, and internal resistance of the connection point, laser welding is currently the preferred choice for many battery manufacturers.

5.How to Understand the Technical Parameters of Battery PACK

| entry name | Parameter indicators |

| composition | 1P24S |

| rated capacity | 280Ah |

| rated voltage | 76.8V |

| rated energy | 21.504kWh |

| Maximum magnification | 0.5CP |

| weight | 138±3kg |

Combination method: 1P24S

S represents series cells, P represents parallel cells, and 1P24S represents 24 series and 1 parallel cells. After series connection, the voltage is doubled, and the rated voltage is 3.2 * 24=76.8V.

Rated capacity: 280Ah

The rated capacity of a battery refers to the capacity of the battery to operate continuously for a long time under rated operating conditions. The rated capacity C of a battery, in ampere hours (Ah), is the product of the discharge current in amperes (A) and the discharge time in hours (h). So 280Ah represents discharge at a maximum current rate of 0.5C, which can last for 2 hours.

Rated energy: 21.504kWh

Rated energy (Wh)=nominal capacity (Ah) * nominal voltage (V), so the total energy that a battery can release is related to both capacity and voltage.