There is a very important process step in the manufacturing of lithium -ion battery -positive and negative pole. During the coating process, the thin area is a marginal area, which can increase the active substance ratio of the electrode sheet to the surface area and increase the energy density and circulation life of the battery. In order to solve the problem of lithium battery edge effects, the formation of a thin area is the key. By optimizing the coating process, coating tools, substrate characteristics, and active material properties, it can effectively control the formation of thin zones. In the formation mechanism of the thin zone, there are many factors that affect the thin zone, such as coating speed, coating thickness, solvent volatilization, etc., and in -depth research and analysis are needed. Therefore, the research and optimization of the thin zone is an important issue in the manufacturing of lithium -ion batteries. By compliance with the precautions such as experimental design, data analysis, material selection, safety issues, environmental protection and exchange and cooperation, it can ensure the smooth progress of the research and optimization of thin zones. The research and optimization of lithium -ion battery thinning areas are of great significance for the development of electric vehicles and energy storage equipment.

The definition and function of the thin area

In the manufacturing of lithium ion batteries, positive and negative pole coating is a very important process step. In the positive and negative pole coating, a thin area refers to the edge area of the active substance coated on the electrode. Its role is to increase the ratio of the active substance of the electrode sheet, improve the electrochemical performance of the electrode sheet, improve the energy density of the battery, the energy density of the battery The cycle life is also to solve the problem of the edge effect of the lithium battery. During the circular charging and discharge of lithium batteries, the active materials on the edge of the battery are often suffered from greater stress, resulting in the battery capacity attenuation and shortened life. Therefore, by thinning the edge of the battery, the impact of the edge effect on the battery performance can be reduced, and the cycle life and energy density of the battery can be improved. The formation of a thin zone has an important impact on the performance of the battery. The research and optimization of the thin zone is an important issue in the manufacturing of lithium -ion batteries.

the method and advantages and disadvantages of thin zone

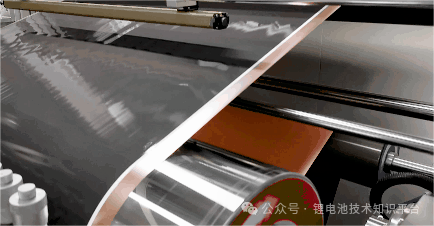

- Mechanical thinning: refers to in the coating process, through roller and pressure, forming some protruding and depression on the surface of positive and negative poles, forming a gradient distribution structure. Low, but it cannot control the position and size of the thin zone, and it is easy to produce unevenness.

- Chemical thinness: refers to adding some specific chemicals to positive and negative electrodes, so that these chemical substances can reflect and generate local thin structures during the coating process. Compared with mechanical thinness, the advantage of chemical thinness is that the location and size of the thin -cut area can be accurately controlled, but the cost is needed to use specific chemicals, which is high.

the factors that affect the formation of thin zone

- The formation of a thin area is due to the common effect of a series of factors in the coating process. The design and material of the coating tool used in the coating process will affect the formation of the thin zone.

- Parameters such as coating speed, coating thickness, and solvent volatility in the coating process will also affect the formation of the thin area. 3. Factors such as the characteristics of the electrode film and the nature of the active substance will also affect the formation of the thin zone.

Considering these factors comprehensively, the formation of a thin area is a complex process, which needs to be studied and analyzed in depth.

optimization measures in thin zone

In order to optimize the formation of the thin zone and improve the performance of the electrode chip, it is necessary to optimize from the aspects of coating process, coating tools, substrate characteristics, and active material properties.

- By improving the coating process parameters, such as coating speed, coating thickness, solvent volatile speed, etc., the formation of thin zone is controlled.

- By improving the design and materials of the coating tool, the formation of thin zone is controlled.

- By improving the characteristics of the electrode film and the nature of the active substance, the formation of the thin area is controlled.

- Through these optimization measures, the formation of thin -cut areas can be effectively controlled, the performance of the electrode chips can be improved, and the energy density and cycle life of the battery can be improved.

In the process of researching and optimizing the thin zone, you need to pay attention to the following matters:

- Experimental design: In the thin -cut area research, a reasonable experimental solution needs to be designed to fully consider the effects of coating process parameters, coating tool design, substrate characteristics, and active material properties, and conduct system experimental verification.

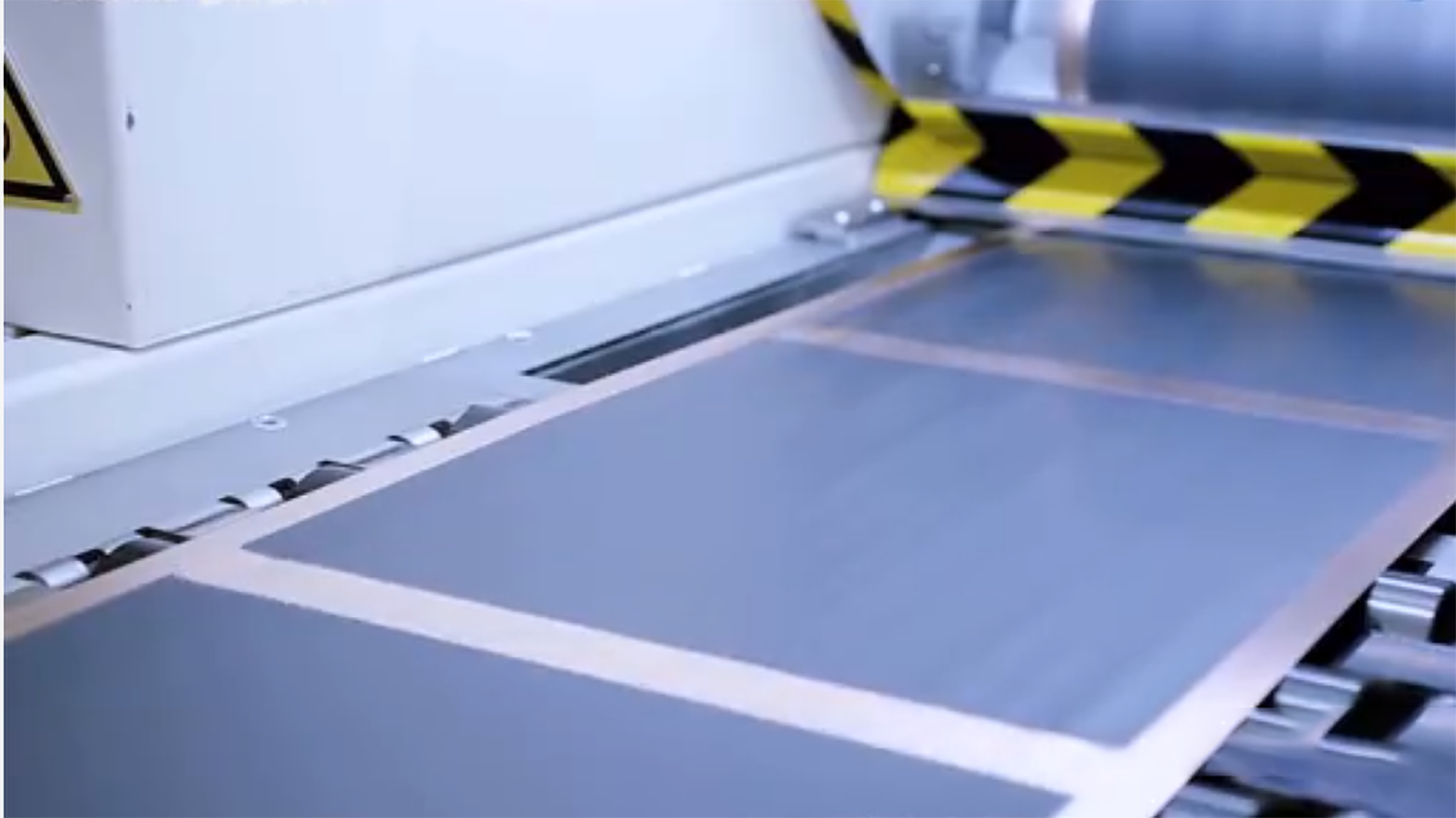

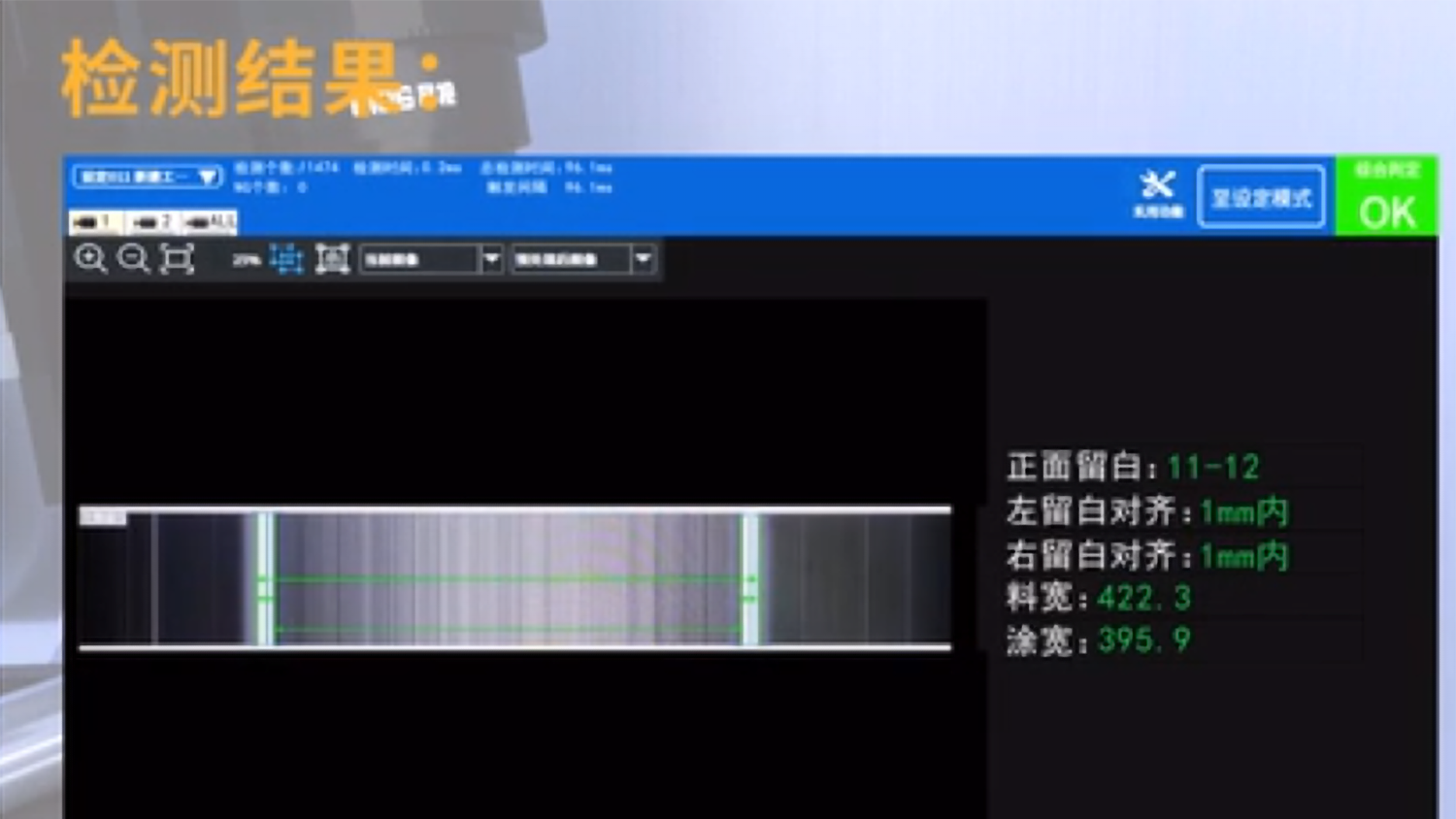

- Data analysis: Accurately analyze and interpret experimental data to ensure the reliability and scientificity of the results of the research results, and provide a reliable basis for optimizing the thin -cut area. Application device measurement: Positive interval The tail of the head is thin and the size measures: X -ray & laser thickness integrated machine, and at the same time measure the density of coating surface and thin size. The negative electrode coating continuous or intervals The edges of the two sides or head and tail are thin. Measurement: β -ray laser thickness integrated machine, and at the same time measure the density of the coating surface, thin thickness, and thinning length.

- Material selection: When conducting a thin area research, you need to choose the appropriate electrode material and active substances to ensure the repetitiveness and comparability of the research results.

- Safety issues: When conducting experimental operations, you need to strictly abide by the safety specifications of the laboratory to ensure the safety in the experiment.

- Environmental protection: During the experiment, we need to pay attention to the treatment of chemicals and waste, and do a good job of environmental protection.

- Exchange and cooperation: When conducting a thin zone research, you can communicate and cooperate with experts and scholars in related fields to discuss issues and promote the sharing and promotion of research results.

- Through the observance of the above precautions, it can ensure the smooth progress of the research and optimization of thin areas, and make positive contributions to the development of lithium -ion battery manufacturing technology.

Conclusion

The thin zone plays a very important role in the manufacturing of lithium -ion batteries. Its formation mechanism is very complicated and requires in -depth research and analysis. By optimizing the coating process, coating tools, substrate characteristics, and active material properties, it can effectively control the formation of the thin zone, improve the performance of the electrode chips, and improve the energy density and cycle life of the battery. It is hoped that through the research and optimization of the thin zone, the advancement of lithium -ion battery manufacturing technology will be promoted to provide a more stable and reliable source of motivation for the development of electric vehicles and energy storage equipment.