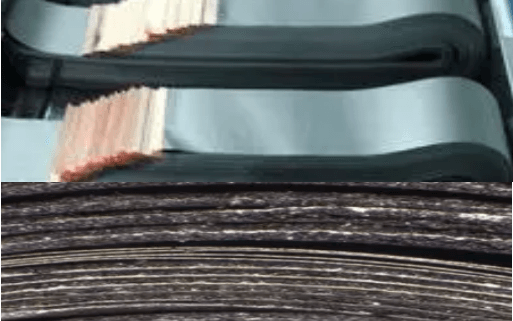

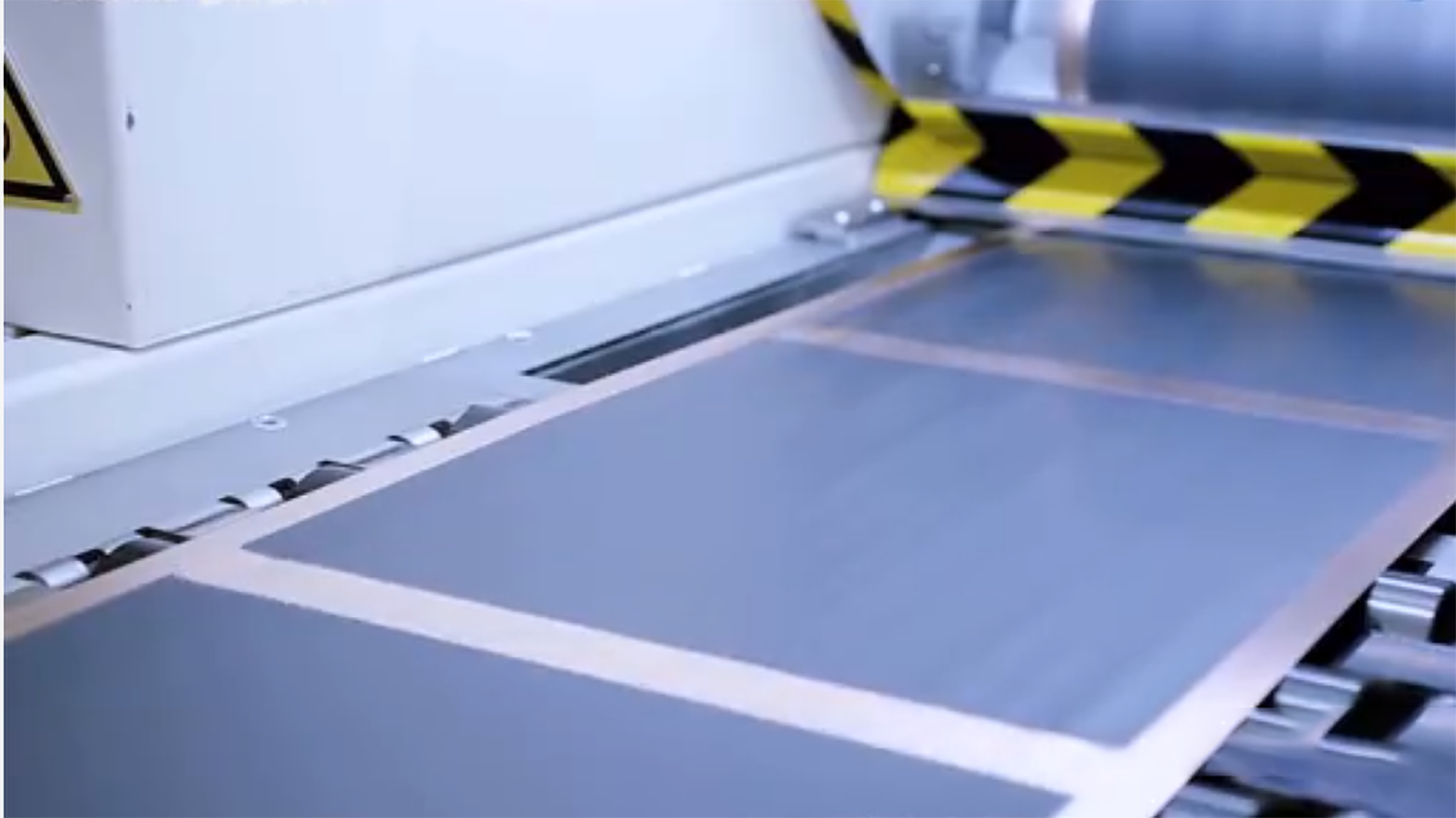

In this study, we have successfully developed a method for fabricating ultra-thin solar cells and transferred them onto lightweight composite fabrics. I have been involved in the entire fabrication process and witnessed the realization of this groundbreaking technology firsthand. In the laboratory, we first prepared a release layer on a polyester film. Subsequently, we deposited a layer of polyimide film on the release layer using chemical vapor deposition, serving as the removable substrate for the cells. Next, we employed two scalable fabrication techniques, slot die coating and screen printing, to create different layers of the cells coated on the polyester. Laser patterning was also utilized for structural definition of the cells. Once the fabrication of the cells was completed, we transferred them onto the lightweight composite fabric. By utilizing a UV-curable adhesive, we laminated the cells and composite fabric together under a vacuum environment. The UV light exposure cured the adhesive, firmly bonding the cells onto the composite fabric. Finally, we peeled off the cells from the polyester substrate, successfully transferring them onto the composite fabric intact. Through our experimental results, we have demonstrated that the performance of cells fabricated through the transfer process is comparable to those directly fabricated on polyester. We have also conducted bending tests, which revealed that the cells can maintain 90% of their initial power conversion efficiency even after undergoing 500 bending cycles. The method for fabricating these ultra-thin solar cells holds significant potential for various applications, particularly in the fields of lightweighting and high-strength applications. Participating in this research has truly highlighted the allure and challenges of scientific inquiry. Through our team’s collective efforts and collaboration, we have overcome numerous obstacles to achieve this significant research breakthrough. I am extremely proud to have been involved and to take pride in our accomplishments. This research paves the way for new possibilities in the future development of renewable energy, and I firmly believe it will have a positive impact on human society.

https://onlinelibrary.wiley.com/doi/10.1002/smtd.202200940

A team of researchers from the Massachusetts Institute of Technology (MIT) has recently developed an astonishingly thin and flexible solar cell, akin to a sheet of paper, that can be attached to surfaces of any kind to harness solar energy.

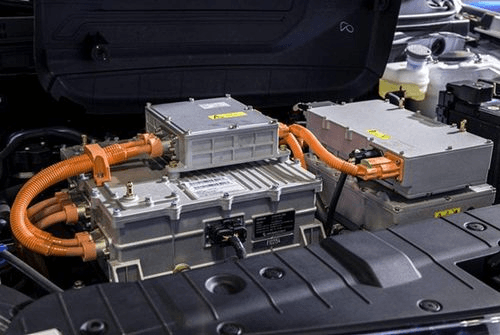

This groundbreaking solar cell, with a thickness even finer than a strand of hair, can be laminated onto various surfaces such as sails, tents, waterproof fabrics, and drone wings, providing extended durability and endurance.

The remarkable findings of this study were published in Small Methods, authored by a collaboration of esteemed individuals including Vladimir Bulovi?, a professor of electrical engineering at MIT, the electrical engineering and computer science graduate student, Mayuran Saravanapavanantham, as well as Jeremiah Mwaura, a research scientist at the Electronics Research Laboratory.

By selecting a composite fabric called Dyneema, the research team printed electrodes onto flat sheets of plastic, which were then adhered to the Dyneema fabric.

However, it is worth noting that this particular solar cell exhibits a relatively low photoelectric conversion efficiency in comparison to conventional silicon solar panels, generating only half the energy per unit area. Nevertheless, it compensates for this drawback by producing a remarkable 18 times the electricity per kilogram.

During testing, the solar cell demonstrated its ability to independently generate approximately 730 watts per kilogram of energy. When deployed on Dyneema fabric, it generated around 370 watts per kilogram.